We, the member of 3B Eng Co., Ltd. is composed of water experts, skilled inspectors and engineers who have lots of experience in each sector. Based on engineering for water treatment and Inspection service, We’ve grown as valuable company by giving better satisfactory to customer.

The vision of water business is to supply substantial water to the nations where suffered from lack of drinking water so that all people can easily take safe & healthy water anywhere anytime. We pledge our vision, doing our best efforts on contributing the mutual prosperity of the mankind and for the sake of world-peace through the prevention of environmental pollution by our advanced technologies

We are able to provide technical service in the field of Procurement service(purchase, process management, inspection and expediting)”, “Testing and Inspection”.

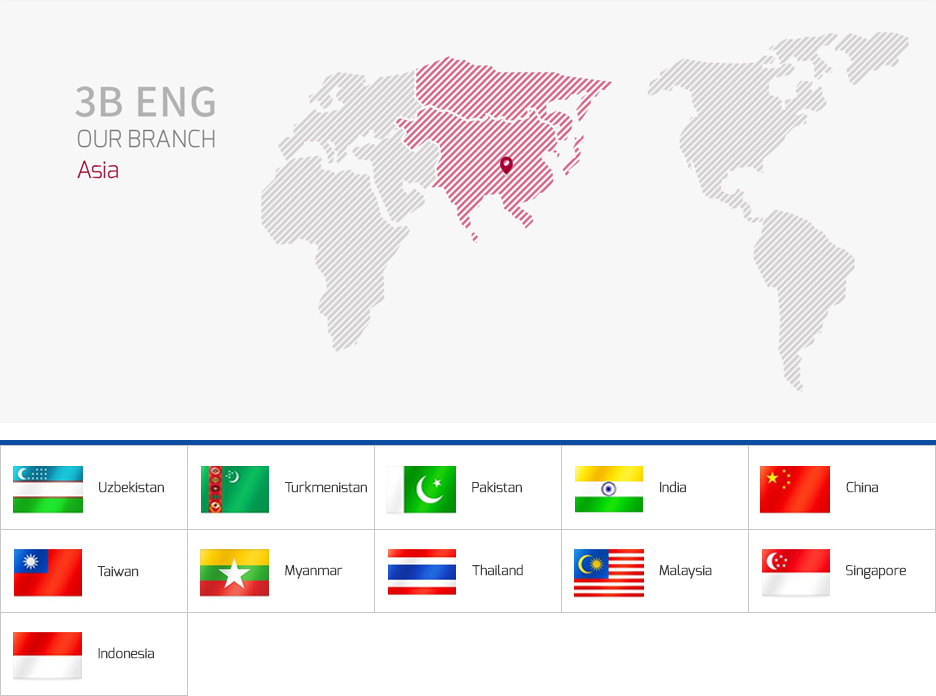

We can cover Korea, Japan, China, Taiwan and Southeast Asia(Thailand, Malaysia, Etc.)

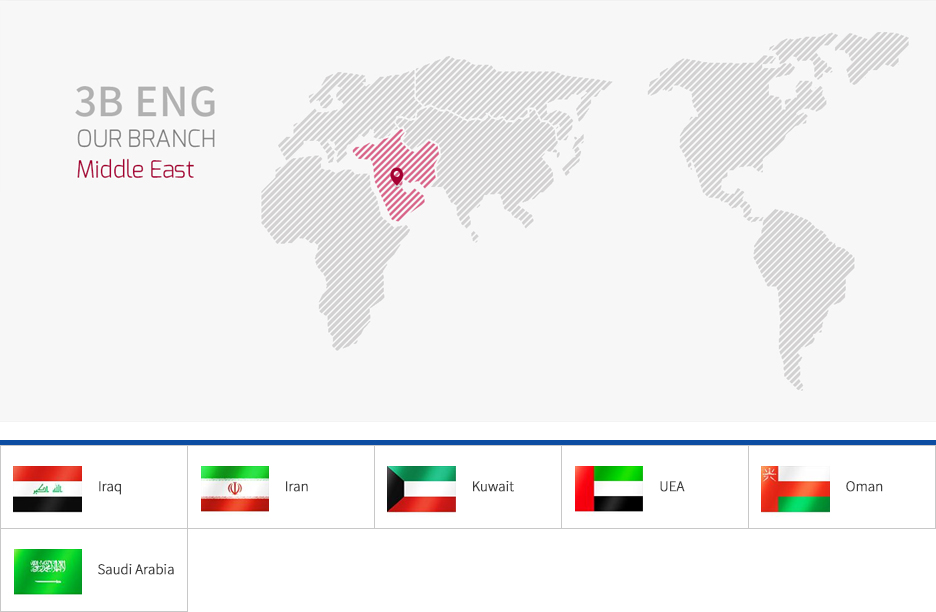

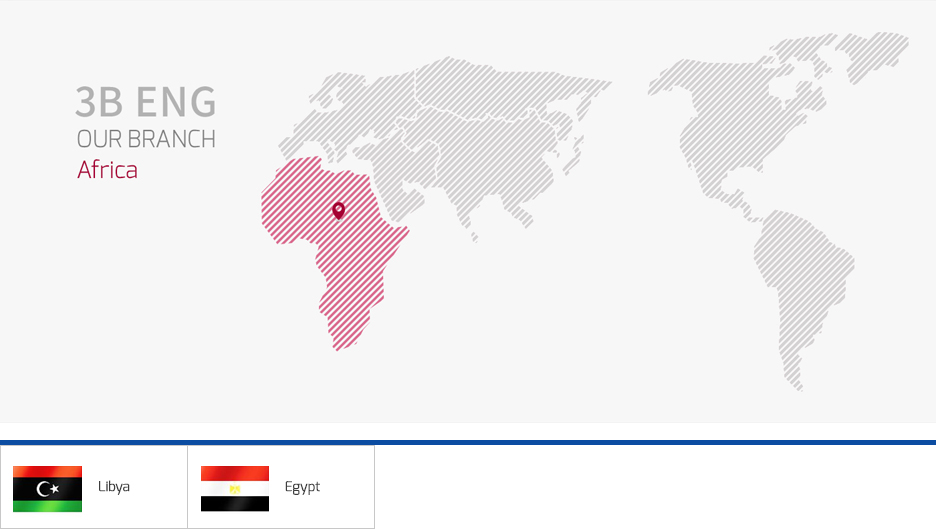

Also, we have branches in abroad and partners, networks all over the world and have showed remarkable capabilities in creating new businesses in cooperation with customers by the combination of skilled engineering techniques and various business models

We would like to thank you customers for encouraging and supporting us.

All the employees will cooperate with each other so that 3B Eng Co., Ltd. may grow into a global business organizer that leads the global market

3B Eng Co., Ltd. C.E.O. Dustin Kwon

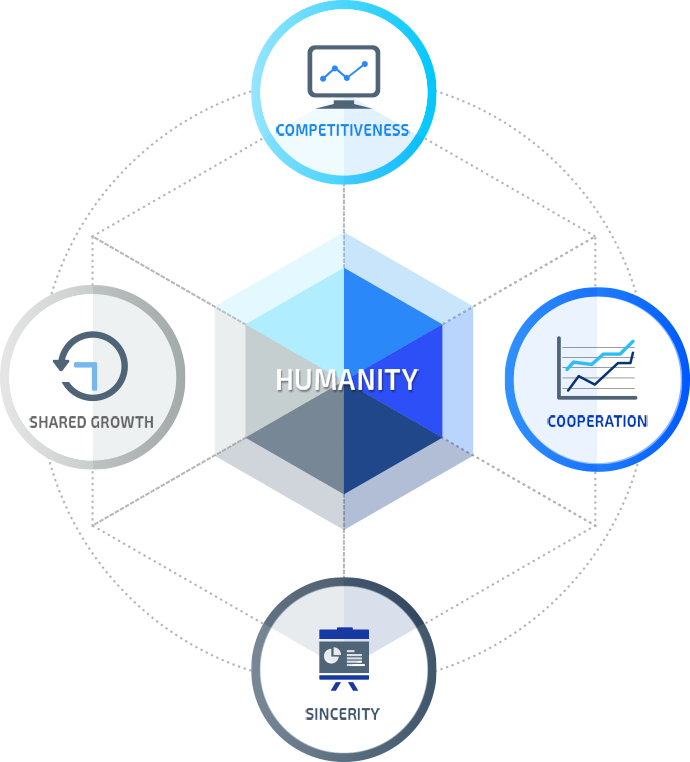

Through the relation and cooperation between all of our employees, we are trying to keep our employees developing and improvement with their experiences and knowledge to give the satisfaction for future projects.

We do our best sincere best with endless passion and commit ourselves to provide customize service for our esteemed clients.

Inspection during fabrication or for status checking are essential engineering services to guarantee that the material conforms to the international and contractual specifications agreed between buyer and supplier whether in raw material, partly or fully fabricated state. The aim of inspection is to ensure that the buyer receives the material or equipment in accordance with their requirements and for a fair and equitable inspection charge.

Through these services, we make certain that equipment satisfying our customers' quality need is provided on a timely basis.

Interpretation of specification and standards

Advice on quality control methods

Determination of inspection and test procedures(through pre-inspection meeting)

Arrangement of work schedules

Determining the conformity to requirements of physical, chemical, and other technological properties of all types of materials used in the fabrication of equipment. Documented test results are then compared with contractual specifications and specified codes and standards. The choice of the operations to be performed depends on the requirements of the assignment and include:

Verification of test reports and identification of mill material certificates.

Witnessing of tests performed by others.

Performance of tests in laboratories.

The object of this service is to verify during welding operations in manufacturer's shops and/or site that all welding operations are executed in accordance with contractual specifications and specified codes and standards.

The choice of operations to be performed depends on the requirements of the assignment and may include:

Reviewing of manufacturer's shop instructions against contractual specification and specified codes and standards.

Witnessing of welding procedure qualification test.

Witnessing qualification tests of welders and welding operators.

Checking that the necessary welding instructions have been issued by the manufacturer.

Checking that all welding operations are being performed in accordance with the instructions issued. Such instructions can cover the type of electrodes to be used, joint preparation and fit-up before welding, preheating requirements, location and sequence of welding passes, completion of intermediary operations such as back chipping, grinding, and cleaning, and post weld heat treatment.

Checking the type and condition of the electrodes employed.

Examination of the welding equipment.

Witnessing of destructive and non-destructive test.

Interpretation of non-destructive test results.

imensional and visual checking of the welded items and of the welds

Performance of destructive and non-destructive test.

Verifying all dimensions which have specified tolerance. The results of the verifications are compared with manufacturing drawings, contractual specifications, specified codes, and standards for their conformity to the requirements of such specifications.

Witnessing performance tests of complete machines or equipment and verifying test results including measured data, corrected data, and calculated performance values which are compared with the applicable specifications to ascertain their conformity to the contractual requirements.

Examination of finished components before packing for general condition and conformity with the applicable specifications, technical characteristics, the number and location of accessories, surface finish, cleanliness, verification of quantity and weight, and general condition of paint and other protective coatings, This inspection is normally accomplished for all accessible parts without necessitating disassembly operations.

The object of this service is to verify the packing material and its marking for its conformity with the specifications. The typical operations performed are

Dentification of material or equipment before packing and checking its conformity with the specifications.

Verification of the protection of packed equipment against humidity, distortion and other sources of damage.

Verification of the conformity of packing material with the contractual specifications and with accepted practice.

Verification of the conformity of marking with the contractual specifications and the handling requirements.

Verification of the correct issue of documents such as packing lists, bills of landing, customs declarations

Additional inspections and testing can be performed to confirm the suitability of packing materials to withstand transportation, loading and unloading operations.

Pre-Shipment Inspections is offered to exporters from the Korea and comprises a detailed inspection of equipment or materials after manufacture, but prior to shipment, The scope includes Quality (Conformance to specification), Quantity, Packing & Marking, Supervision of Loading, A Certificate of Inspection can be provided against a Letter of Credit and authorized by a Chamber of Commerce.

Reports

Analysis of inspection and test results

Advice on improvements

| Process Unit | Pressure Vessels | Rotating Machinery |

|---|---|---|

|

Fired Heaters Furnaces Boilers Cooling Towers Incinerator WHRU Cold Box |

Vessels Tanks Reactors Towers Heat Exchangers Air Fin Coolers HRSG |

Pumps Compressors Fans/Blowers/Roots Blower Gear units Cranes and Hoists Conveyors(Belt, Chain, Bucket) Hydraulic system |

| Package Equipment | Piping Materials | Electrical Equipment |

|---|---|---|

|

VAC packages Air Conditioners Air Handling Unit |

Process Line Pipes Tube, Fittings Fitting, Flanges, Valves Expansion joints Bolt/ Nut, Gasket Steam/Air Trap, Strainer Silencer Sample Cooler |

Transformer Switchgears and MCC Motors Generator Reactors, Resistor Illumination Fixtures UPS Battery and Battery Charger Construction Fitting and Materials |

| Communication System | Instrumentation | Materials |

|---|---|---|

|

Telephone Paging System General Paging System Auto Paging System Wireless Paging System Telephone System Direct Phone Inter Phone System |

Transmitter Recorders, Controller Metering System Probers DCS |

Forgings, Castings Structural Steel Fiber glasses |

This is to compare the progress of activities with a predetermined time schedule or critical path network. This allows detection and analysis of activities which might cause delays, assist in suggesting constructive solutions in order to meet the dates of pre-established programs, and inform the client of the actual situation existing at the manufacturers’ facilities and of all decisions taken or suggested regarding the time schedule.

To verify, during loading and unloading operations, that the correct material or equipment is properly handled and adequately secured on the means of transport. The typical operations performed are:

| From | Client | Project | Equipment | Service |

|---|---|---|---|---|

| 2017 | ARAMCO/L&TH, EMAS | SFNY 4 Decks, Subsea Pipelines & Cables and STP-17 69 KV Circuit Breaker PJT PROJECT | Welded pipes | Inspection |

| 2017 | CCJV | LPIC EPC1 SCU | Plate & Frame heat exchangers | Inspection |

| 2017 | TECHINCO | SADAF and SIRAF Project | API Centrifugal Pumps Sea water pump and Cooling water pumps |

Inspection |

| 2017 | FDH JV | Al Zour Project | Temperature Control Packages | Inspection |

| 2017 | PETRONAS | RAPID Project | Refrigeration Packages | Inspection |

| 2017 | JGC | CGP-3, MHD and SITRA project | Butt weld Fittings | Inspection |

| 2017 | Daewoo | RUC Project | Air Compressors | Inspection |

| 2017 | Daelim | RUC Project | On-Off Valves and Air tanks | Inspection |

| From | Client | Project | Equipment | Service |

|---|---|---|---|---|

| 2016 | Dodsal / KOC |

GC-29, GC-31, Project | Bronze Valves | Inspection |

| 2016 | Dodsal / KOC |

EWTIP Project | MOV Gate, Globe Valves | Inspection |

| 2016 | PDO/PECO | Rarab Harweel project | Air Cooled Heat Exchangers | Inspection |

| 2016 | KOC/Dodsal | Effluent Water Treatment and Injection plant (NK) |

Pipe Spools, Valves, Pumps | Inspection |

| From | Client | Project | Equipment | Service |

|---|---|---|---|---|

| 2015 | SEPCO | Master Gas System Expansion Phase 1 |

Air Cooled Heat Exchangers | Inspection |

| 2015 | TOTAL | KAOMOB Project | HVAC System of FPSO | Inspection |

| 2015 | EXERGY | GEX1300-Saray 12MW Geothermal Power Plant |

Heat Exchangers | Inspection/Expediting |

| 2015 | Daelim | OCU Project | Centrifugal Pumps | Inspection |

| From | Client | Project | Equipment | Service |

|---|---|---|---|---|

| 2014 | JVD/SK E&C | NSPR Project | Big towers and heavy wall pressure vessel | Inspection |

| From | Client | Project | Equipment | Service |

|---|---|---|---|---|

| 2013 | SCI/Tecnicas Reunidas | Gran Chaco Project | Air Cooled Heat Exchangers | Inspection and Expediting |

| 2013 | SECL / Samsung Total | No. 2 Aromatic Complex | Refrigerant Unit | Inspection |

| 2013 | ALSTOM/Hydro-Quebec | Beauharnois Centrale 1 & 3 | Crown, Band & Hub | Inspection |

| 2013 | Daelim / Korea East-West | Ulsan #4 Combined Cycle | Fuel Gas Compressors (65,000 kg/hr) | Inspection |

| 2013 | Daelim / Korea Western P. | 2nd Pyeongtaek CCPP | Fuel Gas Compressors (62,000 kg/hr) | Inspection |

| 2013 | Tecnimont / Braskem-Idesa SAPI |

Etileno XXI-LDPE Plant | Welded Stainless Steel pipes | Inspection |

| 2013 | Daelim Industrial CO. | Po-Cheon LNG Power Plant | Steam Turbine Generator and auxiliaries | Inspection |

| 2013 | SCI/TR | VGO Project | Air Cooled Heat Exchangers | Inspection/Expediting |

| 2013 | GS E&C | UHV Project | Air Cooled Heat Exchangers | Inspection |

| 2013 | SK E&C | WASIT #1 –ADD Project | Air Cooled Heat Exchangers | Inspection |

| 2013 | Chevron | Lianzi Development | Manual Valves | Inspection |

| 2013 | SCI/Tecnicas Reunidas | Gran Chaco Project | Air Cooled Heat Exchangers | Inspection and Expediting |

| 2013 | SECL / Samsung Total | No. 2 Aromatic Complex | Refrigerant Unit | Inspection |

| 2013 | ALSTOM/Hydro-Quebec | Beauharnois Centrale 1 & 3 | Crown, Band & Hub | Inspection |

| 2013 | Daelim / Korea East-West | Ulsan #4 Combined Cycle | Fuel Gas Compressors (65,000 kg/hr) | Inspection |

| 2013 | Daelim / Korea Western P. | 2nd Pyeongtaek CCPP | Fuel Gas Compressors (62,000 kg/hr) | Inspection |

| 2013 | Tecnimont / Braskem-Idesa SAPI |

Etileno XXI-LDPE Plant | Welded Stainless Steel pipes | Inspection |

| 2013 | Daelim Industrial CO. | Po-Cheon LNG Power Plant | Steam Turbine Generator and auxiliaries | Inspection |

| 2013 | Daelim Industrial CO. | Po-Cheon LNG Power Plant | Emergency Diesel Engine Generator | Inspection |

| 2013 | SKE&C / Hanam | Hanam CHP | Heat Recovery Steam Generator (HRSG) (1 Unit, 398 MW) |

Inspection |

| 2013 | SKE&C / Tufanbeyli | Thermal Power Plant (3 units x 150 MW) |

Pipe Spool of WET SCRUBBER | Inspection |

| From | Client | Project | Equipment | Service |

|---|---|---|---|---|

| 2012 | SECL / Samsung Total | No. 2 Aromatic Complex | Air Cooled Heat Exchangers | Inspection |

| 2012 | Turkish Petroleum Refineries Corporation |

IZMIT Refinery Resid Upgrading PJT | Heavy Wall Vessel, Alloy Shell & Tube H/E, Shell & Tube H/E Hydrogen Unit | Inspection |

| 2012 | Shell Development Australia (SDA) |

Prelude Floating LNG Project | Marine Bolier (Steam drums, Economizer Heater, Super heater, EVA Header etc) Riser and Feeder connecting pipes |

Inspection |

| 2012 | GLIS-Korea/Israel EC Ltd | RAMAT, HOVAV Unit 9 | Boiler Feed water pumps | Inspection |

| 2012 | Hyundai E&C / JRC | Jurong Rock Cavern Phase 1 | MOV Butterfly valves (Double/Triple type) | Inspection |

| 2012 | GLIS-Korea/Israel EC Ltd | Orot Rabin Power Station #5 & #6 | Motor for Vacuum Belt Filters | Inspection |

| 2012 | ARAMCO | Yanbu Export Refinery PJT | Atmospheric Column, Kerosene Strippers | Inspection |

| 2012 | SKE&C / ARAMCO | WASIT #1, #3 and #4 Project | Air Cooled Heat Exchangers | Inspection |

| 2012 | Techicas Reunidas | Guang-Dong Zhuhai LNG Project - Phase 1 | Cryogenic Butterfly Valves | Inspection |

| 2012 | GL Abu Dhabi / Dodsal E&C | Habshan Sulphur Granulation | Carrying Idler & Stand | Inspection |

| 2012 | SKE&C / ARAMCO | Yanbu Export Refinery EPC-2 | Casting Valves of Carbon Steel, Low alloy Steel and Stainless steel | Inspection |

| 2012 | Ministry of Oil State Co., BAGHDAD, IRAQ |

Oil projects (SCOP) | Casting Valves of carbon steel | Inspection |

| 2012 | SKE&C / ARAMCO | Yanbu Export Refinery EPC-2 | Air Cooled Heat Exchangers | Inspection |

| From | Client | Project | Equipment | Service |

|---|---|---|---|---|

| 2011 | SECL/ UAE SHAH GAS | UAE SHAH GAS Development Package 4 Utilities & Offsites | Chilled Water Refrigeration Package | Inspection |

| 2011 | Petrofac | South Yoloten Gas Development | Air Cooled Heat Exchangers | Inspection |

| 2011 | TRACTEBEL ENGINEERING BELGIUM | Chilcauno Power Station ADD-ON Project | Heat Recovery Steam Generator (HRSG) | Inspection |

| 2011 | Hitachi Plant Technologies, Ltd. (HPT) | SSP Project | Pressure Vessels | Inspection |

| 2011 | Kuwait Oil Company | MAA to Sabiya and Doha Power Stations |

DPDU Refrigerant Transfer Vacuum Pump | Inspection |

| 2011 | SK E&C / SK Lubricants | H project | Centrifugal pumps | Inspection |

| 2011 | KOC/SK E&C | BS-132 | Air Cooled Heat Exchangers | Inspection |

| 2011 | BV-China | Zhejiang Ningbo LNG Terminal | Air Release and Vacuum Break Valves | Inspection |

| 2011 | The Consortium of AI Arrab Contracting Company and SEPCO III |

RAS Az Zawr Power and Desalination Plant – Phase 1 Package Power Plant |

Heat Recovery Steam Generators (HRSG) | Inspection |

| 2011 | PDO/GS E&C | SNDC Phase-1 | Air Cooled Heat Exchangers | Inspection |

| From | Client | Project | Equipment | Service |

|---|---|---|---|---|

| 2010 | GASCO | HABSHAN-5 | Pressure Vessels & Clad Vessels | Inspection |

| 2010 | SATORP | Jubail Export Refinery | FCC Tower and Pressure Vessel | Inspection |

| 2010 | SATORP | Jubail Export Refinery | Low alloy Heat Exchangers | Inspection |

| 2010 | SATORP | Jubail Export Refinery | Air Cooled Heat Exchangers | Inspection |

| 2010 | SKEC | Jubail Export Refinery | Copper & Nickel Heat Exchangers | Inspection |

| 2010 | SKEC | Jubail Export Refinery | Air Dryer Packager Unit | Inspection |

| 2010 | CTCI | Jubail Export Refinery | Air Dryer Packager Unit | Inspection |

| 2010 | KUMHO / Daelim Industrial Co., LTD |

KPA-III Project | Centrifugal Pumps | Inspection |

| 2010 | Assmang Iron Ore | KEP 16MT | 6,000 tph ROM Stacker, 3,800 tph ROM Reclaimer |

Inspection |

| 2010 | MGR/L&T | Vemagiri - 2 | HRSG (15 Modules-Vertical Type) | Survey for factory, foundry |

| Customer | Location | Motor | Q'ty | Model | Capacity [m3/h] | Pressure [kg/cm2] | Delivery |

|---|---|---|---|---|---|---|---|

| Compair/ Neimenggu Hengkun Huagong |

China | 746KW | 3 | WB900 | 6,600 | 9.0 | Feb-15 |

| Compair/ Neimenggu Hengkun Huagong |

China | 746KW | 3 | WB900 | 6,600 | 9.0 | Feb-15 |

| Compair/ Neimenggu Hengkun Huagong |

China | 746KW | 3 | WB900 | 6,600 | 9.0 | Feb-15 |

| Compair/ Neimenggu Hengkun Huagong |

China | 746KW | 3 | WB900 | 6,600 | 9.0 | Feb-15 |

| Customer | Location | Motor | Q'ty | Model | Capacity [m3/h] | Pressure [kg/cm2] | Delivery |

|---|---|---|---|---|---|---|---|

| GD(HK)/Taisuo Hejing steel company | China | 821KW | 5 | WB1200 | 7,200N | 8.5 | May-14 |

| SK Chemical | Korea | 448KW | 1 | SG600L1P1 | 5,423N | 3.1 | May-14 |

| Korea Southern Power Co.,Ltd | Korea | 895KW | 4 | WB1080 | 6,400 | 8.8 | May-14 |

| POSCO Engineering | Brazil | 1,640KW | 3 | WB2000 | 12,500 N | 7.0 | Jun-14 |

| SCCC/Shandong tongli luntai | China | 746KW | 1 | WB900 | 7,200 | 8.5 | Nov-14 |

| POSCO Plantec | Brazil | 410KW | 2 | WB520 | 2,050 N | 8.0 | Jun-14 |

| SCCC/Yangzhou hengrun haiyang zhonggong | China | 1,194KW | 2 | WB1500 | 12,000 | 8.5 | Feb-14 |

| GD/Shandong chenfan | China | 1,492KW | 4 | WB1500 | 15,000 | 8.0 | Mar-14 |

| SCCC/Hancheng tiangong yejin | China | 746KW | 3 | WB900 | 5,640N | 8.5 | Feb-14 |

| SCCC/Hunchun duojinshu | China | 671Kw | 3 | WB900 | 6,000N | 8.0 | Mar-14 |

| GS Construction / sin-boryeong Power plant |

Korea | 895KW | 4 | WB1080 | 6,600S | 8.8 | Jul-14 |

| GD/Shandong lutai fangzhi | China | 1,119KW | 1 | WB1500 | 1200 | 7.0 | Apr-14 |

| HYOSUNG Co. | Korea | 1,119KW | 1 | WB1120 | 1200 | 8.0 | May-14 |

| Compair/Henan Baililian huaxue | China | 746KW | 2 | WB900 | 5,800N | 7.0 | May-14 |

| Compair/Fujian zhengqi gaoxian | China | 1641KW | 1 | WB2000 | 15,000N | 8.0 | May-14 |

| HYUNDAI STEEL | Korea | 448KW | 1 | WB550 | 5,000 | 7.5 | Jun-14 |

| DAEHO Textile | Korea | 448KW | 1 | WB550 | 5,000 | 7.0 | Aug-14 |

| POSCO | Korea | 746KW | 1 | WB1080 | 6,000N | 8.0 | Aug-14 |

| Compair/Shandong yongsheng Xiangjiao | China | 746KW | 1 | WB1080 | 7,200 | 8.0 | Sep-14 |

| Compair/Shandong Xinghongyuan luntai | China | 746KW | 1 | WB900 | 7,200 | 8.0 | Sep-14 |

| Compair/Shandong Shengshitailai Xiangjiao | China | 746KW | 1 | WB900 | 7,200 | 8.5 | Sep-14 |

| Compair/Shandong Shangneng Shiye | China | 746KW | 1 | WB900 | 6,000N | 8.0 | Sep-14 |

| Compair/Henan Maisike Electron Material | China | 448KW | 2 | WB600 | 3,400 | 9.0 | Sep-14 |

| Compair/Neimenggu Keweibo Shengwu | China | 821Kw | 1 | WB1500L2 | 12,000 | 2.5 | Sep-14 |

| POSCO ENG / Thailand POSCO TCS CGL | Thailand | 1119KW | 3 | WB1100 | 8,000N | 8.5 | Dec-14 |

| POSCO | Korea | 522KW | 1 | WB550 | 5,000 | 8.0 | Dec-14 |

| GD/Weiqiao Aluminium & Electricity | China | 1679KW | 4 | WB2000 | 18,000 | 8.0 | Oct-14 |

| GD/Weiqiao Aluminium & Electricity | China | 1679KW | 4 | WB2000 | 18,000 | 8.0 | Dec-14 |

| SCCC/Shandong longyue xiangjiao | China | 746KW | 1 | WB900 | 7,200 | 8.5 | Sep-14 |

| SCCC/Shandong longyue xiangjiao | China | 746KW | 1 | WB900 | 7,200 | 8.5 | Nov-14 |

| SCCC/Shandong xindalu xiangjiao | China | 746KW | 1 | WB900 | 6,000 | 8.5 | Oct-14 |

| GD/Xinkunming steel | China | 1492KW | 1 | WB2000H3 | 12,000 | 8.0 | Oct-14 |

| SCCC/Shandong jiangshan gaofenzi cailiao | China | 1194KW | 1 | WB1500 | 10,500 | 10.0 | Oct-14 |

| SCCC/Henan yuguang jinqian | China | 149KW | 1 | ST600S1 | 4,800N | 12.0 | Dec-14 |

| Samguang Glass | Korea | 224KW | 2 | WB540L2 | 3,300 | 3.5 | Nov-14 |

| SCCC/Shandong tongli luntai | China | 746KW | 1 | WB900 | 7,200 | 8.5 | Nov-14 |

| Customer | Location | Motor | Q'ty | Model | Capacity [m3/h] | Pressure [kg/cm2] | Delivery |

|---|---|---|---|---|---|---|---|

| POSCO E&C | Indonesia | 1566KW | 3 | WB2000 | 12,500 N | 7.0 | Feb-13 |

| POSCO E&C | Indonesia | 1417KW | 4 | WB2000 | 11,500 N | 8.0 | Apr-13 |

| POSCO | Korea | 932KW | 1 | WB1080 | 6,000 N | 9.5 | May-13 |

| Hyundai Oil Bank (Steam MVR) | Korea | 3281KW | 3 | SV43H3P1 | 60 ton | 13.50 | Jun-13 |

| SCCC/Yunnan yuxi xianfu steel | China | 1,119KW | 1 | WB1500 | 10,000 | 8.0 | Nov-13 |

| Shenhua (Baotou) Charcoal Chemical Industry | China | 1491KW | 5 | WB2000 | 12,000 N | 8.0 | Jan-13 |

| Luoyang zhongxing zhonggong | China | 522KW | 3 | WB600 | 4,800 | 8.0 | Feb-13 |

| Tiancheng Yaolun | China | 2610KW | 2 | WB3000 | 28,000 | 5.2 | Jul-13 |

| SCCC/Zhangjiagang Tezhong xianwei | China | 1,119KW | 1 | WB1500 | 12,000 | 7.0 | Oct-13 |

| SCCC/Neimenggu whhai qianlishan | China | 1,119KW | 1 | WB1500 | 10,200 | 8.0 | Nov-13 |

| Tiancheng Yaolun | China | 671KW | 2 | WB900 | 7,200 | 8.0 | Jul-13 |

| POSCO ENG | Korea | 373KW | 3 | WB525 | 2,500 | 9.0 | Mar-13 |

| POSCO ENG | Korea | 522KW | 1 | WB550 | 4,950 | 9.0 | Jun-13 |

| Houying jituan | China | 746KW | 3 | WB900 | 7,200 | 8.5 | Apr-13 |

| SCCC/SHANDONG JIUTAI HUAGONG | China | 1,417KW | 2 | WB2000 | 13,000 | 6.3 | Dec-13 |

| POSCO Construction | Brazil | 746KW | 4 | WB700 | 5,000 N | 7.0 | Sep-13 |

| YOUNGIL GLASS | Korea | 186KW | 1 | WB520L2 | 2,400 | 3.5 | May-13 |

| YOUNGIL GLASS | Korea | 224KW | 1 | WB520L2 | 2,940 | 3.5 | May-13 |

| YIPIN SHENGWU | China | 895KW | 2 | WB1200 | 6,600 | 8.0 | Apr-13 |

| Shanghai Chenghou NXBM | China | 820KW | 1 | WB1200 | 6,600 | 7.2 | Jun-13 |

| Shandong hengyu | China | 522KW | 1 | WB600 | 6,700 N | 8.0 | May-13 |

| SCCC/Neimeng wuhai xilaifeng | China | 1,119KW | 1 | WB1500 | 4,800 | 8.0 | Nov-13 |

| Guizhou hangkong fadongji yanjiuyuan | China | 3,729KW | 1 | ST5000H3 | 10,200 | 8.0 | Dec-13 |

| Guizhou hangkong fadongji yanjiuyuan | China | 1,715KW | 1 | ST5000S2 | 42,000 | 25.0 | Dec-13 |

| DONGIL PAPER | Korea | 447KW | 1 | WB550 | 5,000 | 8.0 | May-13 |

| DONGIL PAPER | Korea | 447KW | 1 | WB550 | 5,000 | 8.0 | May-13 |

| DONGIL PAPER | Korea | 447KW | 1 | WB550 | 5,000 | 8.0 | May-13 |

| HANWHA | Korea | 261KW | 1 | ST350 | 3,000 | 7.0 | Jun-13 |

| Yunnan Kungang Zhiyangchang | China | 1,491KW | 1 | ST1500H4N2 | 10,000 N | 16.0 | Jun-13 |

| Hebei yingli nengyuan | China | 597KW | 1 | WB700 | 6,000 | 8.5 | May-13 |

| Henan yuguang jinqian | China | 1,640KW | 2 | WB2000 | 15,000 N | 8.0 | May-13 |

| Jinrui dianzi | China | 1,119KW | 1 | WB1500 | 12,000 | 8.0 | May-13 |

| Jinrui dianzi | China | 447KW | 1 | WB600 | 4,800 | 8.0 | May-13 |

| Shenghua(Baotou)Charcoal Chemical industry | China | 1,491KW | 3 | WB2000 | 12,000 N | 8.0 | Jul-13 |

| Zibo ruiyin chemical industry | China | 1,044KW | 1 | ST1200H3 | 8,000 N | 10.0 | Jul-13 |

| Whkuang yingkou | China | 1,790KW | 4 | WB2000 | 14,400 N | 10.0 | Jul-13 |

| Fujian wuhang buxiugang | China | 932KW | 1 | WB1200 | 10,000 | 8.0 | Jun-13 |

| Hyundai Steel (Incheon) | Korea | 895KW | 1 | WB1100 | 9,200 | 7.0 | Sep-13 |

| Hyosung (Ulsan) | Korea | 1,119KW | 1 | WB1120 | 12,000 | 8.0 | Jul-13 |

| GD/Guizhou lvye | China | 1,715KW | 1 | WB2000 | 18,000 | 6.0 | Jul-13 |

| SCCC/Henan tianguan | China | 2,238KW | 1 | WB3000 | 25200 | 4.2 | Sep-13 |

| GD/Yunnan lixin lvye | China | 1,194KW | 5 | ST1500H3 | 10,200 | 8.5 | Sep-13 |

| GD/Guangzhou Xinzhongguo zaochuanchang | China | 933KW | 4 | WB1200 | 8,400 | 9.0 | Sep-13 |

| SCCC/SHCH-Louyang nuoya jinggong | China | 1,865KW | 1 | WB3000 | 17,800N | 5.0 | Nov-13 |

| HANSOL | Korea | 671KW | 1 | WB1070 | 6,000N | 7.0 | Sep-13 |

| BDM/Hebei zhongsheng Bio- technological | China | 821KW | 1 | WB1200L2 | 10620 | 2.5 | Aug-13 |

| GD/Sichuan anyishengwu | China | 336KW | 1 | WB600L2 | 4,800 | 3.0 | Dec-13 |

| Ningxia Yulin Huagong | China | 671KW | 1 | WB900 | 5,400 N | 7.0 | Mar-13 |

| Customer | Location | Motor | Q'ty | Model | Capacity [m3/h] | Pressure [kg/cm2] | Delivery |

|---|---|---|---|---|---|---|---|

| POSCO E&C | Indonesia | 746KW | 4 | WB700 | 5,000 N | 8.8 | Nov-12 |

| Yunnan Kungang Zhiyangchang | China | 1491KW | 1 | ST1500H4N2 | 10,000 N | 16.0 | Sep-12 |

| Jiangying Jinma | China | 2237KW | 1 | WB3000 | 23,300 N | 5.0 | Oct-12 |

| KP Chemical (Steam MVR) | Korea | 4317KW | 1 | SV22H3P2 | 33 ton | 14.03 | Nov-12 |

| Guangxi Shenglong Metallurgy company | China | 1119KW | 4 | WB1500 | 9,000 N | 8.5 | Jul-12 |

| Yuxi Steel | China | 1119KW | 2 | WB1500 | 10,800 | 8.0 | Oct-12 |

| Jianglin qiche | China | 596KW | 3 | WB900 | 6,600 | 7.5 | Jul-12 |

| HYOSUNG Co. | Korea | 1119KW | 1 | WB1120 | 10,000 N | 8.0 | Sep-12 |

| Ningxia Yulin Huagong | China | 671KW | 1 | WB900 | 5,400 N | 7.0 | Aug-12 |

| Shanghai chenghou-NXBM | China | WB1200 | 1 | WB900 | 6,500 N | 7.0 | Aug-12 |

| SeAH Besteel Co. | Korea | WB1100 | 2 | WB900 | 8,000 N | 8.0 | Nov-12 |

| POSCO | Korea | 1044KW | 1 | WB1100 | 7,600 N | 7.5 | Dec-12 |

| Dongyuan keji | China | WB2000H3 | 5 | 14,750 N | 8.5 | 9.0 | Dec-12 |

| Ningxia Lanbaihei active carbon | China | 820KW | 1 | WB1200 | 6,900 N | 7.0 | Dec-12 |

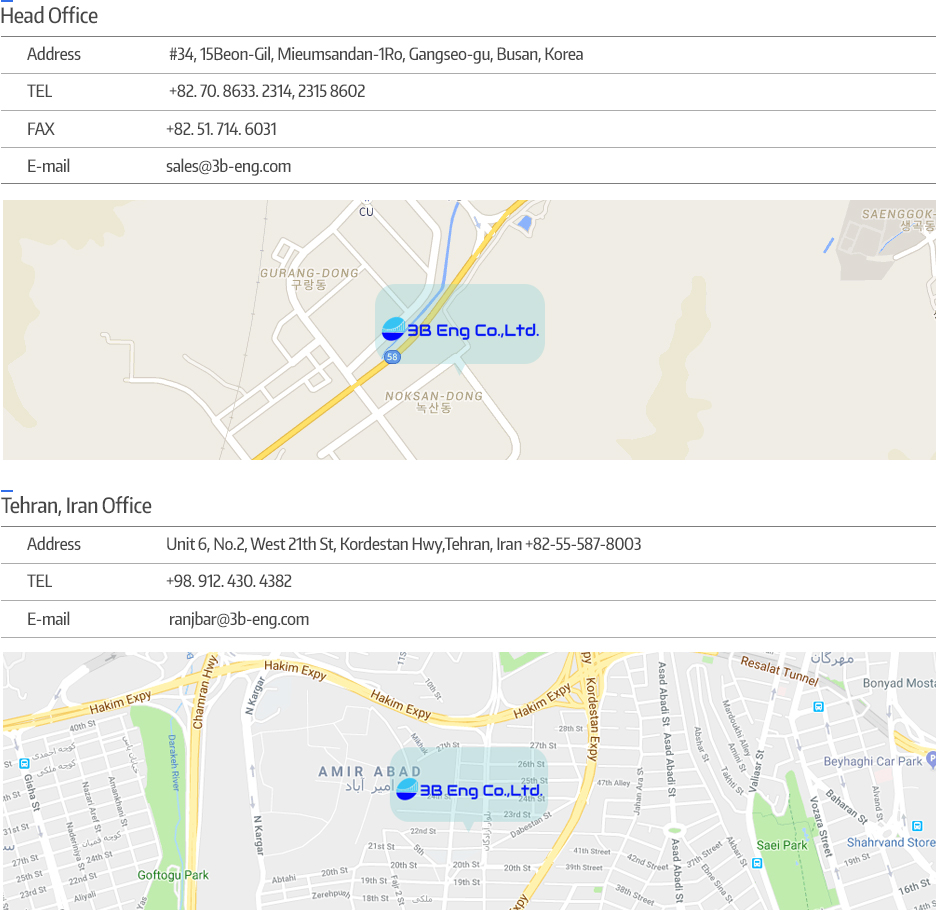

Address : #34, 15Beon-Gil, Mieumsandan-1Ro, Gangseo-gu, Busan, Korea

Tel : +82. 70. 8633. 2314,2315 8602 / Fax : +82. 51. 714. 6031

Copyright ⓒ 2018 3B Eng Co., Ltd. ALL RIGHTS RESERVED.